Keep your metal fabrication project on track and on budget with Air Stream Sheet Metal Inc.

Keep your metal fabrication project on track and on budget with Air Stream Sheet Metal Inc.

A strong weld joint is critical for your enclosures and kiosks.

Not only will it protect the tech or valuable items inside, it will help ensure your product’s durability and meet cabinet specs such as NEMA ratings.

While some sheet metal joining options like rivets, screws or pins are necessary, using too much hardware in your design could cause delays in lead time or even threaten your product’s quality or reliability. Air Stream Sheet Metal follows design for manufacturing (DFM) principles and uses alternative joining techniques to help reduce unnecessary hardware in your product.

These options can make your product easier to manufacture while ensuring it meets quality and tolerance requirements.

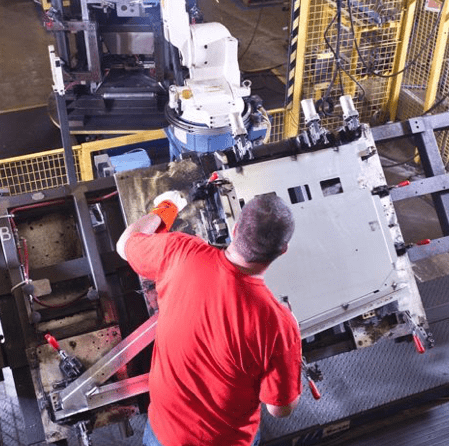

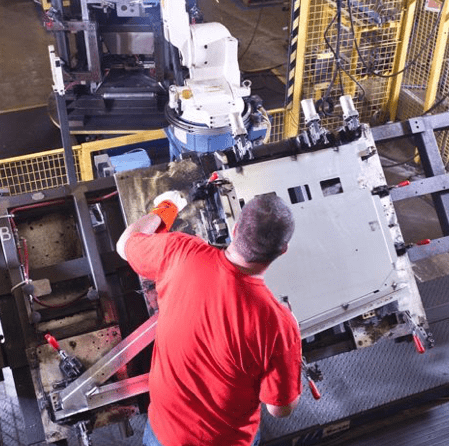

A successfully welded product relies on both the methods and the skill of the welder. Our talented craftsmen and women have deep experience and industry knowledge, which is supported by the leading edge automated welding technology.